PLUG 'N' PLAY - Revolutionalizing through Modularity

Attributable to today’s technological inventions, business and communication has evolved in the most unexpected ways possible. Today, innovations being thought of in some office space in USA are being manufactured in geographically distant countries and being assembled in a small town in Africa. This is not just happening in metro cities of the world, but even the remotest parts of the world are not untouched with this process.

So, if a branded pair of shoes can be ordered in some small part of the world, which might lack even basic infrastructural resources, then why not, a School?

Design philosophy:

There are several remote villages in the world that lack the infrastructure and facilities of a school. Gaining an education is important, but how does one achieve it when the nearest school is 20km away? With the ever-increasing population growth in so many developing countries, the demand for education also increases. The investment of time and affordability of this provision plays a major role in deciding how one can provide schooling in these areas. Can we build a school that can be speedily constructed in the most efficient manner possible and provide for flexible multi-functional spaces that can be used for different activities, yet be affordable for poor people to gain an education?

Plug ‘n’ Play is an approach to the design of a modular school that offers the end user with the flexibility and ease to “plug” various materials as per the functional requirement, climate, cost and regional availability. A modular school could effectively increase the affordability of a structure where the spaces could be transformed according to the need of the users. The school will thus provide creative and comfortable spaces for the children. It would be cost and time efficient as well as help provide local employment.

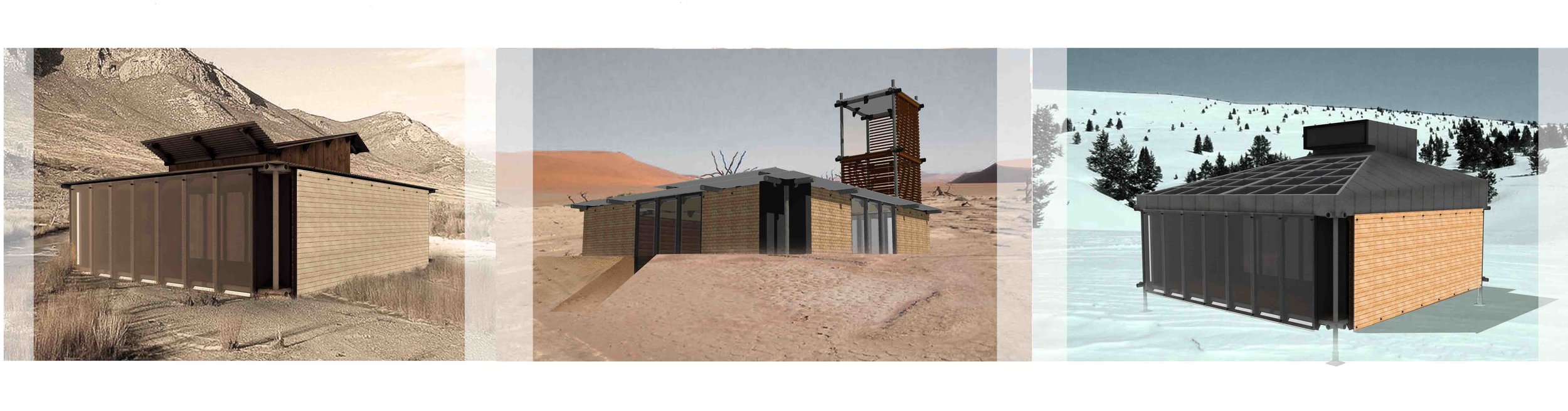

Context responsiveness:

A basic modular structure has been designed to take advantage of the local conditions and material of the region where it is going to be located. The module can be transported and reassembled anywhere in the world.

Similar to a DIY set, the schools structural skeleton will come packed in boxes along with a manual of constructing it in a regional language, along with self-explanatory images. The manual will also suggest a suitable position for reconstructing the structure and possible orientations. Pre-engineered metal pipes and fittings are used to provide framework to the module, also providing modularity and flexibility; as well as additional panels that can be installed as per need.

Once the basic structure is upright, the local building materials and traditional knowledge of construction is utilized to make the floors, walls, ceilings, windows, boards etc. The use of local materials provides a great advantage in terms of making the school building more climatically and socially responsive to the location in which it has to be constructed. Also the locals are comfortable using their indigenous materials and are well versed with the process of its construction. Responding to the context with its traditional heating and cooling methods integrated with this modular approach gives way to sustainability and flexibility in the design of the school.

The integration of the modular structure with the locally available skill set and materials/technology would also add a sense of identity or belongingness to the technologically advanced modular system, hence creating a feeling of ownership by the users of the school.

Modular construction system:

The use of local materials available in different regions along with a permanent set of pre-engineered metal framework suffices for an easy-to-build structure.

(1)- Structure

Pre-engineered metal pipes and fittings are used to provide framework to the module. Cleats and brackets are bolted to the structure to provide joinery for floor, wall and roofing panels. The framework provides modularity and flexibility and panels can be installed as per the requirement.

(2)- Flooring

Wood-wool sandwich floor panels are used to retain heat radiated from the central heating system. Wood being imported widely in the region with wool being a local produce, the sandwich panel can be assembled locally. Central heating coil is deployed beneath the wood floor for radiative heating. The coil is embedded in the ground to minimize heat losses to the environment.

(3)- Walling

Adobe bricks, wood-wool sandwich, doubly glazed polycarbonate form the walling system for the module. With the MS structure in place, various combinations of walling panels can be used as per need and climatic orientation.

(4)- Roofing

Corrugated sheet and waterproof canvas with wool in-fill are used to form the roofing system in the module. Layering technique issued to maximize thermal retention within the structure. A solar collector is added to the roof to further increase the heat intake from the south.

Design Strategies:

The modular structure is arranged in a cluster format. All spaces are accessed from a common foyer which opens into a small enclosed courtyard. The heating system is placed centrally, heating the spaces through the floor and exhausting the smoke through a central chimney. Classrooms and sports hall are provided with an additional space that acts as a buffer from the outside environment.

The roof traps the heat from the south-glazed facade during the afternoon hours and radiates it to the space below throughout the day. The glazed facade traps the heat which is stored in the high thermal-mass layer and radiated to the inner spaces. The height of the indoor spaces is as low as 2.5 m to minimize heat losses to the surrounding environment.

Open spaces

The proposal activates the whole premises by creating hierarchical open spaces for open learning and playing.

Solar Collector

The roof traps the heat from the south-glazed facade during the afternoon hours and radiates it to the space below throughout the day.

Trombe Wall

The glazed facade traps the heat which is stored in the high thermal-mass layer and radiated to the inner spaces. The height of the indoor spaces is as low as 2.5 m to minimize heat losses to the surrounding environment.

Local Materials

The panels can be covered by using locally available materials - canvas and sheep wool. Mud walls form an exterior layer providing high thermal mass thereby minimizing heat loss.

Heating System

Inspired from the ancient Ondol heating system of transferring heating through the floor. Heat source can be fuel based or electric as per the site conditions.

The heating system is placed centrally, heating the spaces through the floor and exhausting the smoke through a central chimney.